The Problem:

Use an additive manufacturing process to design and produce a part of high geometrical complexity which cannot be done by other manufacturing processes.

The Results:

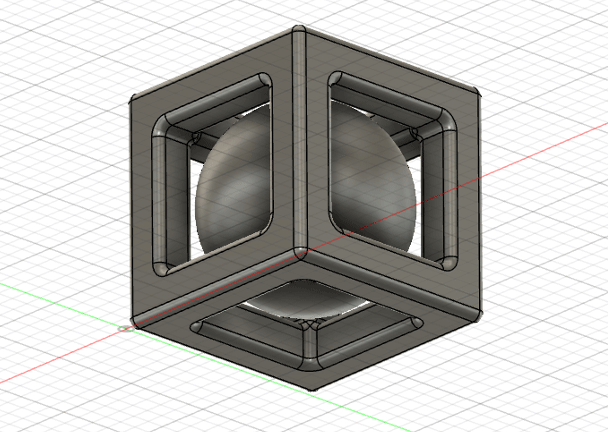

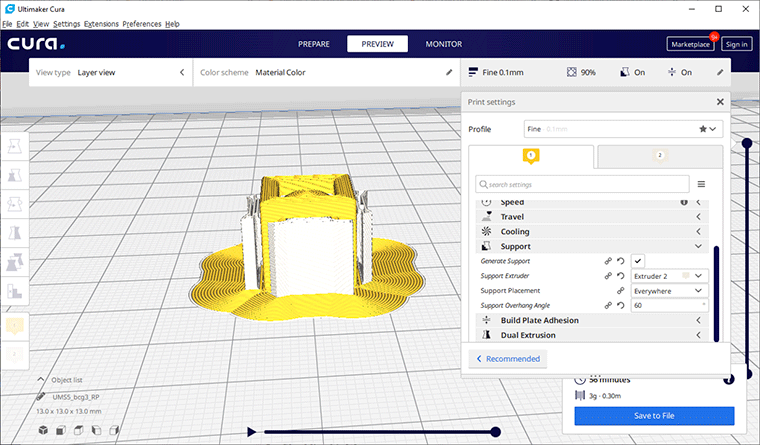

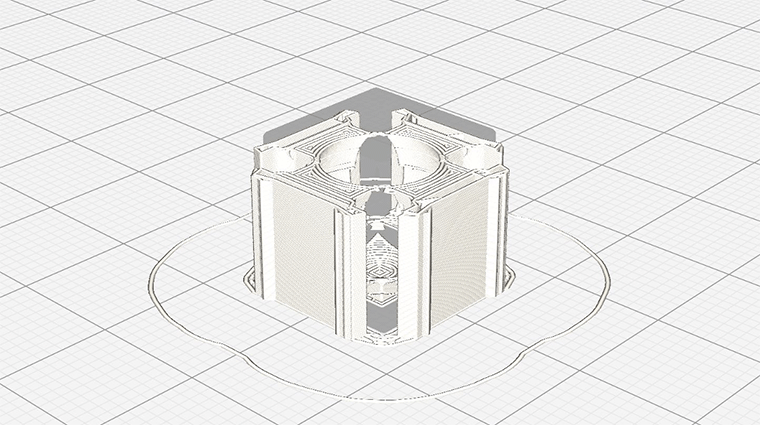

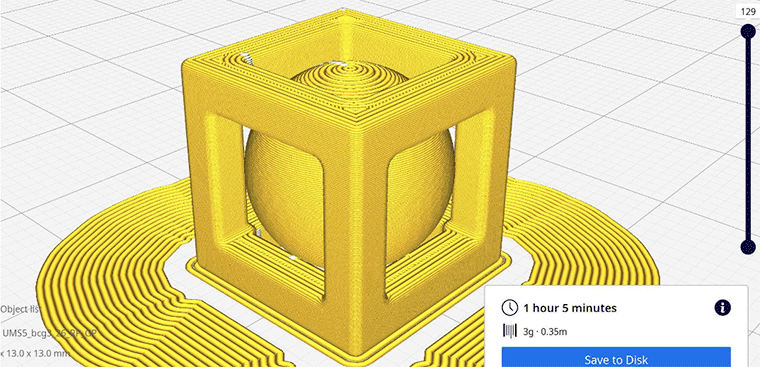

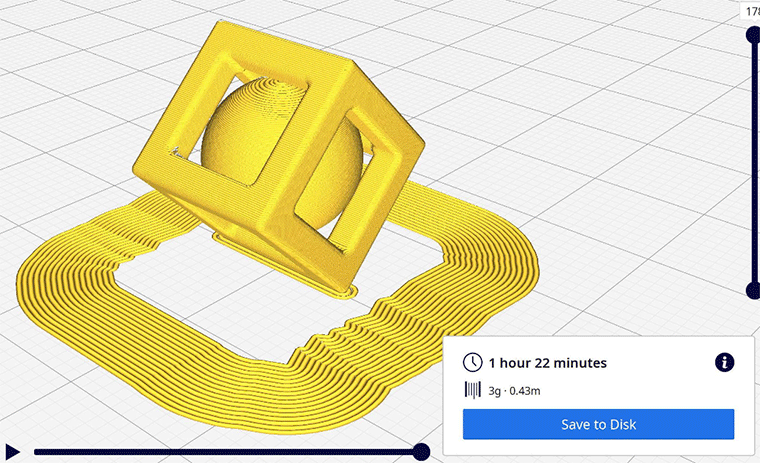

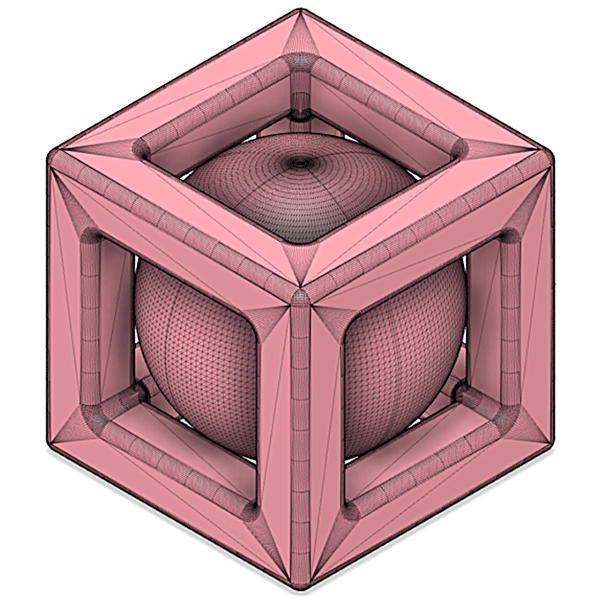

A small team of students including myself designed a general part using CAD software. Then, we integrated the CAD designs with 3D printing software, to slice and print our model. A sphere enclosed in a cubic frame was designed to demonstrate the unique abilities of Fused Deposition Modeling (FDM). This part would be impossible or prohibitively expensive to manufacture using traditional manufacturing techniques.

The print settings were tuned for high fidelity and quality, with 0.1mm layer height and 90% infill. The material chosen for the part was PLA given its low cost and ease of use. Our design and production produced a mechanically stable, and relatively high-quality surface-finished part.

Project Skills:

- Concept Designs

- CAD using Fusion 360

- Team Project Scheduling

- Process Improvements

- Presentation & Reports